Why will people, not just technology, future-proof supply chains?

For many years, “agility” in logistics has been an elusive goal – something all boards aspire to but few achieve. In his opening remarks at Air Cargo Southeast Asia 2025, Radu Palamario, Group CEO of Alcott Global, challenged the industry to redefine what agility means in an age of volatility, automation and consolidation.

Palamario distilled resilience into three fundamentals: mindset, technology and talent.

“Mindset first – because uncertainty is constant. Technology second – because it has never been faster or cheaper to deploy it. And people last – because they are what ultimately defines us.”

He added: “You can’t beat someone who uses pen and paper if they have world-class digital tools. But equally, the best software in the world is useless without the right leaders to implement it.”

In an industry characterized by unpredictability, his message resonated with an audience of freight forwarders, airport operators, and logistics executives looking for a balance between automation and adaptability.

“Technology will change everything we do,” Palamario concluded. “The question is not whether we accept it – but whether our people are ready to lead this change.”

Mentality before machines

With so many uncontrollable variables, Palamario believes that resilience begins with mindset. He cited Roger Bannister’s four-minute story and compared it to leadership under pressure: “Before Bannister, scientists said it was impossible. Then one man did it, and suddenly thousands did it. We can’t control turmoil, but we can control our outlook.”

He urged logistics leaders to stop viewing technology as expensive or complex. “The limiting belief I see is that digital tools are only for the DHLs or DSVs of the world. This is outdated. Today’s modular and scalable systems can be deployed in a matter of weeks and pay for themselves just as quickly.”

He cited examples of transportation management or invoice reconciliation tools that achieve ROI within a month. “Implementing technology has never been easier – the bottleneck is faith,” he said.

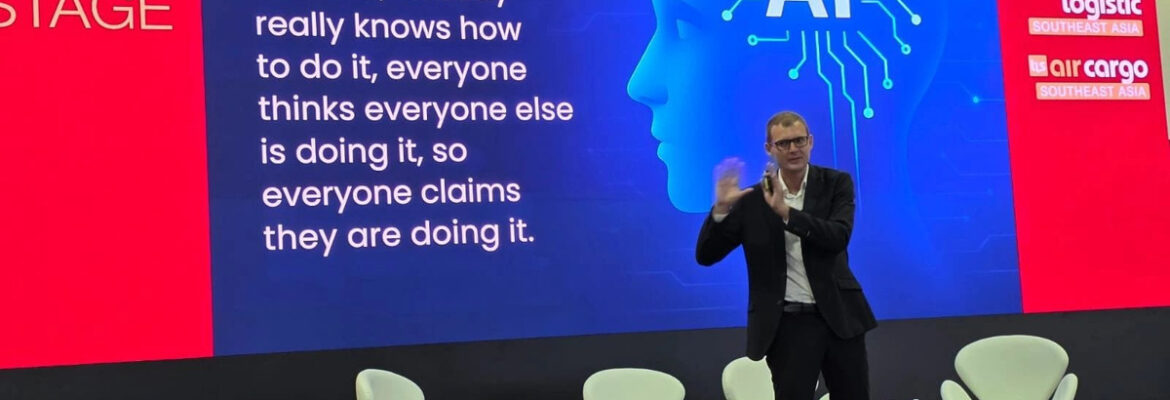

The next artificial intelligence segmentation

Although wary of the hype, Palamario predicted that AI will fundamentally reshape logistics within four years. “One consulting firm I work with expects to reduce operating costs by 10% through automation and artificial intelligence within 18 months,” he noted. “That 10% head start becomes a competitive moat. You can’t simply wait and imitate the first mover – they are already more efficient and have more capital to reinvest.”

The implication, he said, is that companies should start experimenting now rather than waiting for “total clarity.” Early adopters using AI to forecast, route optimization, or process automation will widen the gap compared to their slower peers.

People at the core

Ultimately, Palamario insisted, “Technology alone will not make a company future-proof — people will.” He praised companies like Maersk and PSA Singapore for pairing digital systems with extensive operator training. “They are investing in teams that already understand how to use AI and robotics to make better decisions,” he said.

But finding such talent is becoming more difficult. In one executive search for an AI-powered procurement role, his team screened 350 candidates and found only one truly qualified. He added: “This type of person is worth his weight in gold.” “If you have those things, keep them — pay them well, give them room to experiment. If you don’t have them, find them.”

For leaders, this means reevaluating team composition. “Determine who embraces technology and who resists it. The latter will slow you down. Those who ‘get it’ must be empowered to drive change across departments.”